Techno-Economic Analysis: A Tool for Lean Start-Ups

In today’s fiercely competitive clean-tech industry, the concept of "lean" has emerged as a powerful methodology for start-ups. Discover the power of techno-economic modeling as a tool for companies to ask critical questions and gain strategic insights, paving the way to rapid commercialization and positioning them for success.

The concept of "lean" has risen to the forefront these days, as a way to denote projects that have optimized their production processes and increased profitability. The idea behind lean projects is to identify and eliminate waste from a process, thereby reducing costs and maximizing productivity. Waste in this context can be thought of not only in terms of physical streams but also in terms of inefficient allocation of effort and capital. By adopting a lean approach, companies can cut unnecessary expenditures and redirect resources to higher-value activities.

The Lean Clean-Tech Start-Up

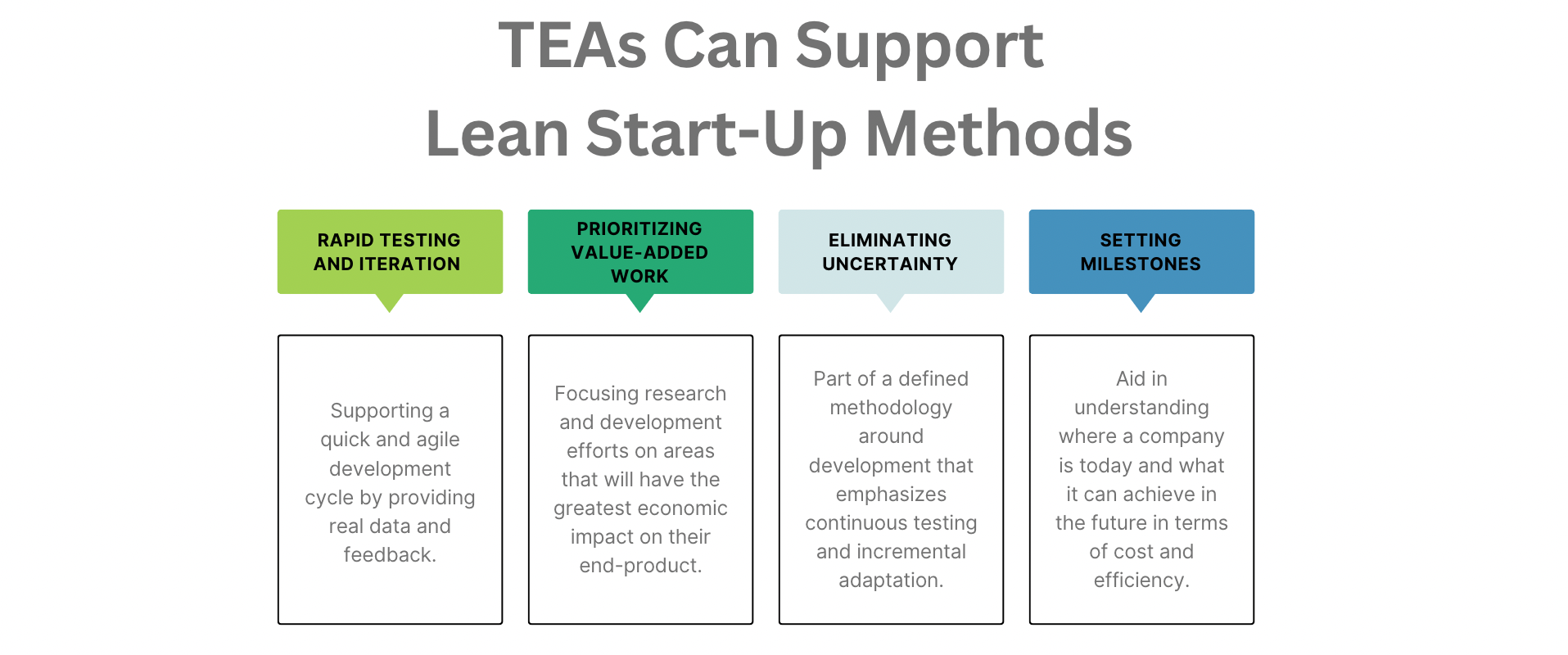

Start-ups have embraced lean practices as a means to accelerate success by adopting tools to shorten development cycles and minimize wasted resources. To test hypotheses and support agile technology development, techno-economic analyses (TEAs) can serve as a critical point in the feedback loop, providing companies with a means to rapidly focus research efforts, obtain real results, and facilitate iterative design. An effective TEA can support several lean methods:

Image 1. Lean start-up methods that can be supported by techno-economic modeling.

These methods are crucial for launching projects quickly and inexpensively while reducing risk. Despite their evident value, TEAs present many challenges to clean-tech start-ups. Accurately simulating a process at pilot or commercial scale often proves to be a difficult task, requiring involvement of outside consultants with expertise in plant design and operation. Next Rung Technology has used our industry experience to develop countless TEAs that have become invaluable tools to our clients as they strive to scale their operations.

The Next Rung Technology Approach to TEA

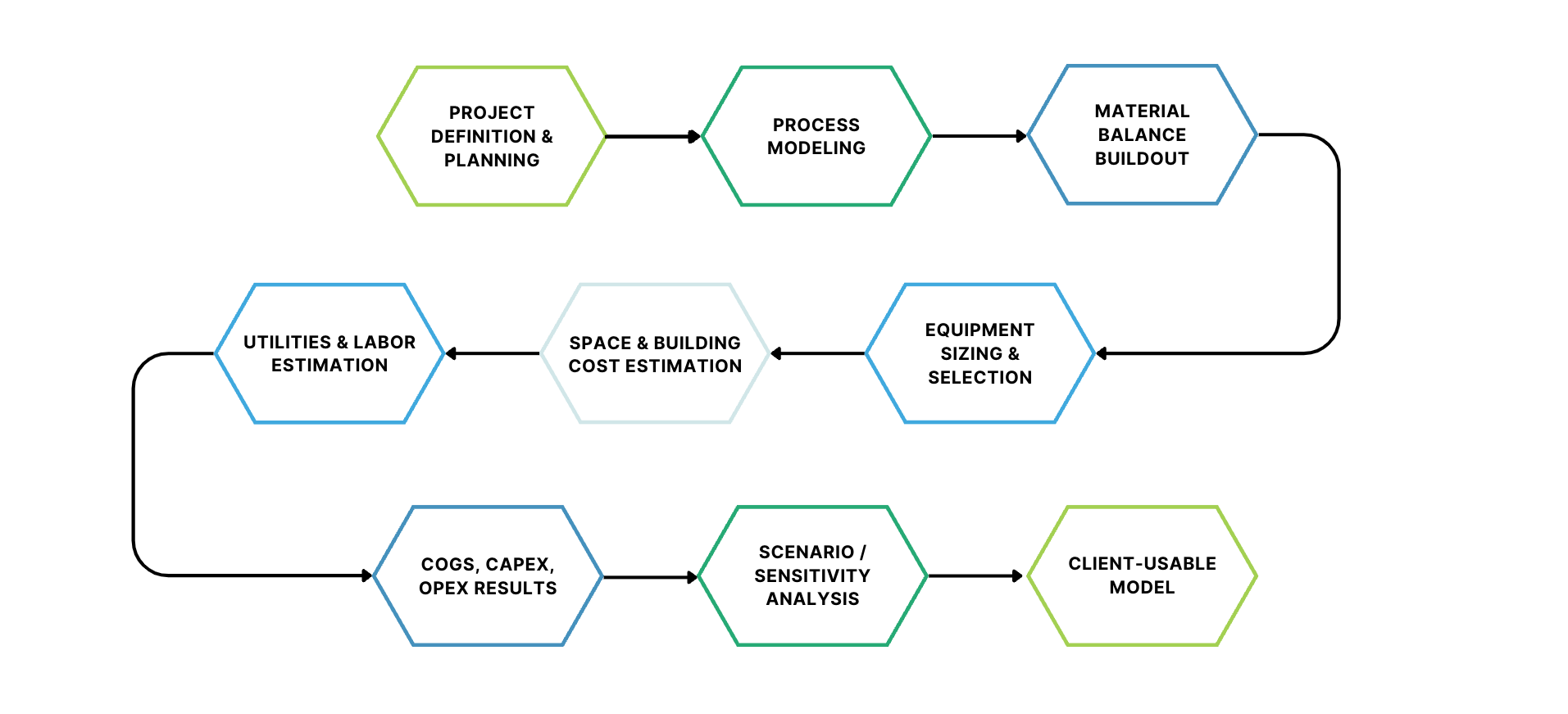

The Next Rung team takes a collaborative and forward-thinking approach when conducting techno-economic analyses, working closely with clients to tailor each TEA model to their unique processes and development interests.

Image 2. The Next Rung TEA process from project definition to a ready-to-use model.

While techno-economic models can become overwhelming in their depth and complexity, Next Rung prioritizes simplicity over marginal gains in accuracy. Our aim is to create an iterative and workable tool for clients to actively use throughout the development of their technology, rather than providing a single-point third-party assessment of economics. As a smaller firm, NRT is able to stay highly dynamic in our approach— regular feedback from the client to ensures the development of the model meets their needs, which may change as the process unfolds.

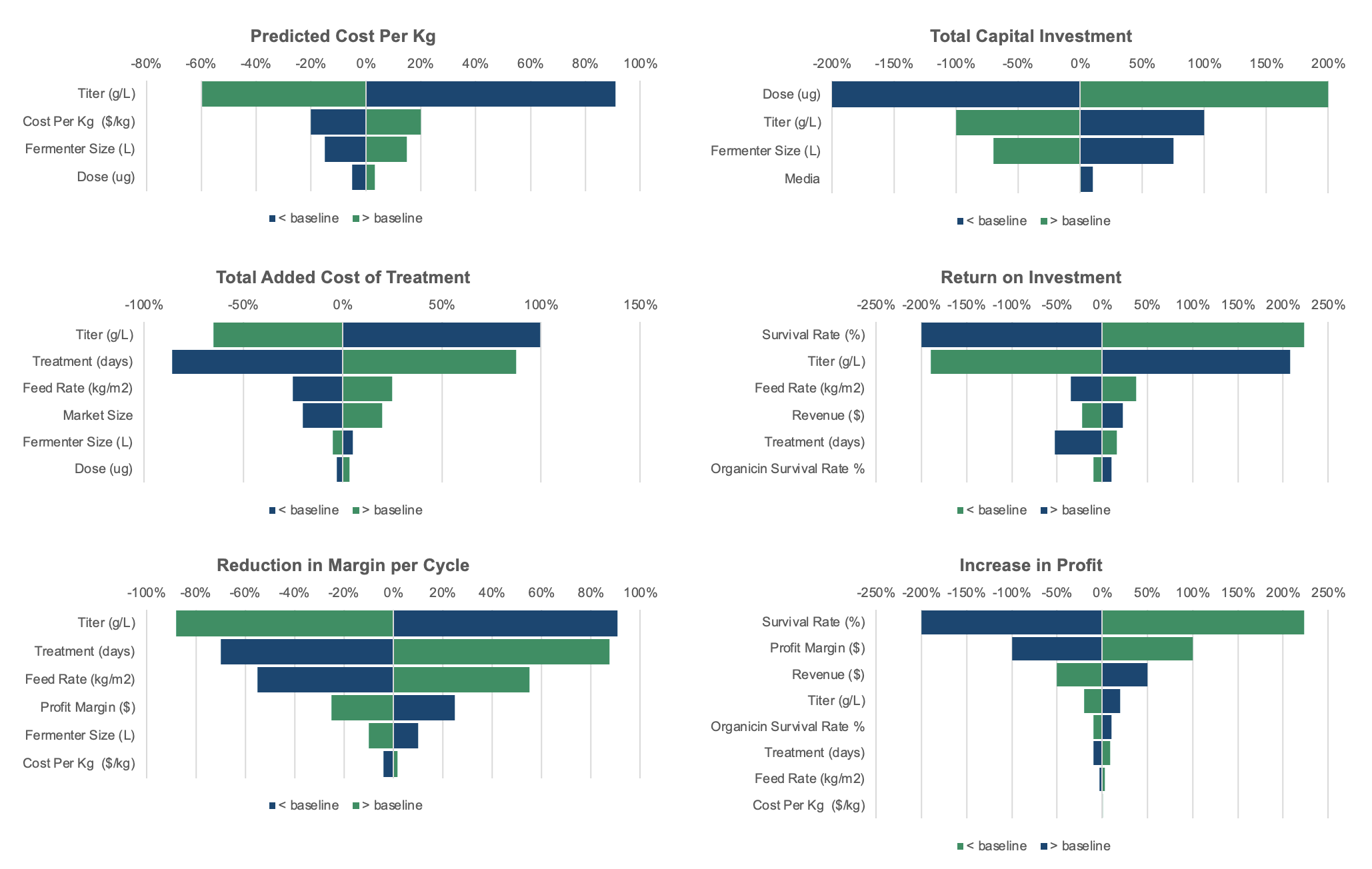

Image 3. A standard Next Rung TEA faceplate.

The final model features a user-friendly faceplate that enables scenario modeling, highlights key outcomes such as production capacity or environmental metrics, and provides a detailed breakdown of economics including cost of goods sold (COGS), operating expenses (OPEX), and capital expenses (CAPEX). Our comprehensive model is summarized in a clear and concise display of essential metrics that are vital to companies seeking funding, aiming to minimize costs, or deciding where to direct funding for technology development.

By leveraging the power of TEA and adopting a lean mindset, the following companies described below were able to reduce costs and position themselves for sustainable growth.

Case Study #1: Helping a Client Prioritize R&D for a Lab-Scale Process

Image 4. Identifying most influential drivers to focus R&D efforts during product development.

An early-stage biopharmaceutical company wanted to develop a TEA to understand the economics of their existing bench-scale process at the commercial scale. A goal of the process was to narrow down the company’s broad search for process drivers that could improve performance and optimize production while reducing overall costs.

The results of the TEA identified which parameters had the greatest impact, providing guidance on where to focus their research efforts. This project helped the company avoid one of the most common pitfalls for start-ups— chasing down process improvements with minimal potential for economic gains— to avoid wasted R&D efforts and operate in a lean manner.

Case Study #2: Eliminating Uncertainty Around a Client’s Downstream Process

Image 5. An examination of financial projections and performance outcomes across 8 downstream processing scenarios.

After working with Next Rung to build their initial TEA model, a later-stage food ingredient start-up sought to screen eight downstream processing options being considered for their product. Rather than dedicating company resources toward extensive laboratory testing, the client utilized the modeling tool for initial evaluations of their options.

Next Rung built multiple parallel models to compare final product purity, overall recovery, and other critical process outcomes. The models identified the downstream options with higher projected OPEX, perhaps due to increased labor or utility requirements, versus cases that would likely require more expensive equipment, thus incurring a larger capital investment. By uncovering hidden expenses and inefficiencies, the client was able to take the lean approach and reduce their options to the most promising processes. Through the TEA process, the client achieved a better understanding of their costs and a refined focus for process design efforts before scaling up commercially.

For us, a TEA is not just a cost estimation exercise. It is also an opportunity to critically assess clients’ process design parameters and performance, leading to better outcomes overall. In building a TEA, Next Rung values the process as much as the final product— keeping our clients as active collaborators and maintaining a flexible and iterative model is key to using TEA as a lean tool. If you are curious if our TEA services are right for you, please don’t hesitate to reach out , we would love to discuss what you are working on!